A new concept predicts a long future for the projectile technology

Engineers combine the advantages of solid Swiss mechanical engineering art with highly specialized know-how and the digital possibilities of today.

The result is a flexible modular system that extends the functionality of projectile looms in a modular way. Significantly higher fabric qualities are achieved at higher output and reduced machine load.

The customer avoids high investments and can continue to rely on his proven brands.

These services were designed for the machines of «Maschinenfabrik Rüti», «Sulzer Rüti» and «Sulzer Textil».

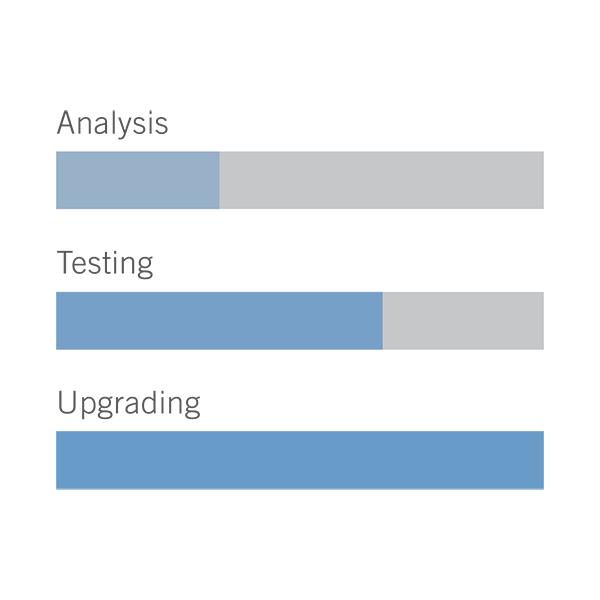

The Service

You want a specific fabric quality, more performance or a relief of your machine. Define your objectives. We transfer them one-to-one to your machine.

We use high-speed cameras and metrological sensors for well-founded analysis and technical data collection.

We then convert your projectile loom with prepared modules from our conversion kit to meet your individual needs.

The result is a machine that works at much more favorable conditions or better than a new model – with a lifetime of another 30 to 40 years.

The Advantage

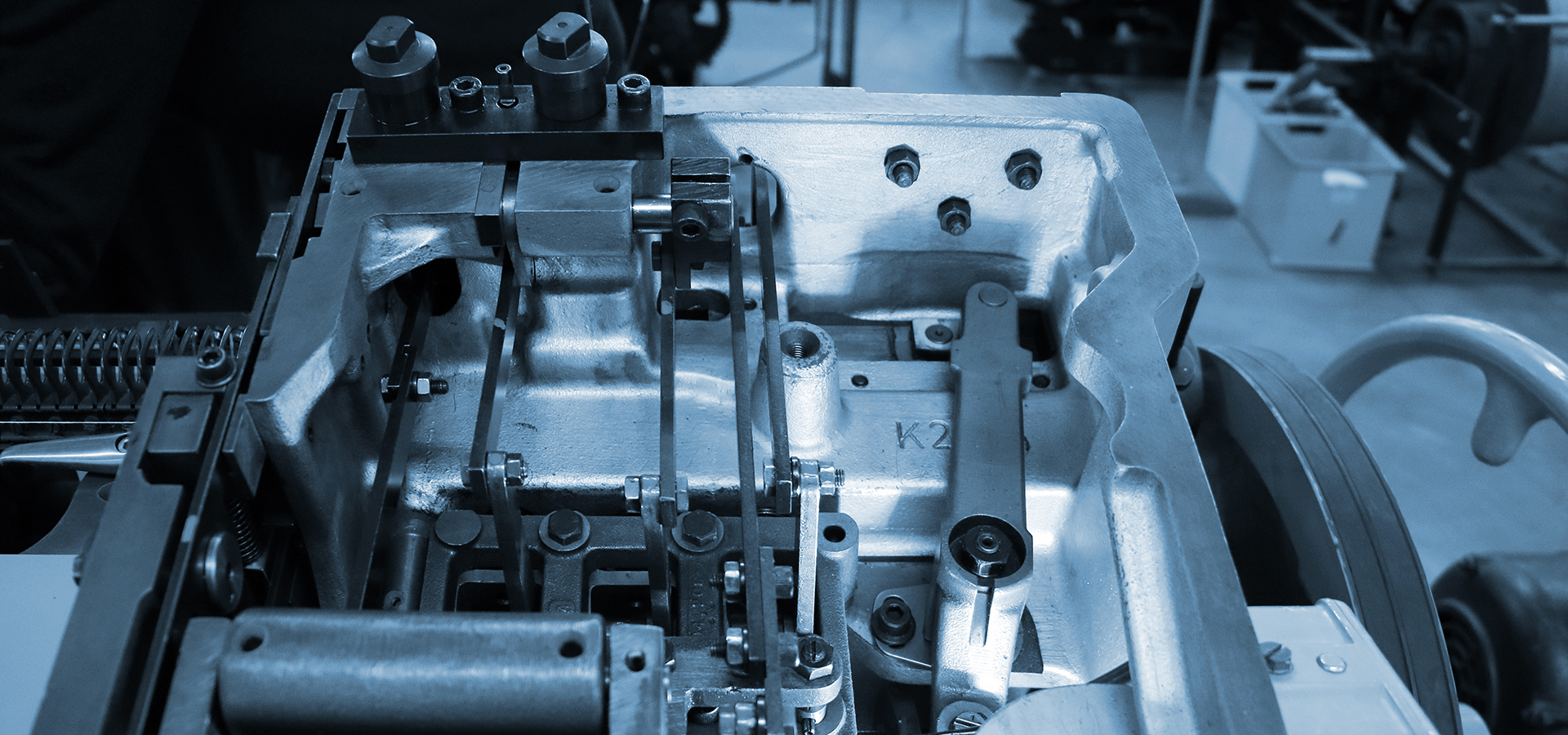

Projectile weaving machines (TW11, PS, PU, PLean, P7100, P7150, P7200, P7250, P7300, P7300HP) convince on every level with accurate and robust Swiss engineering design.

Many have been in use for over 30 years and can easily produce another 30 to 40 years. Comparable models of other brands are disposed of after five, maximum ten years.

Compared to other weaving systems, the insertion system of the projectile weaving machine has clear advantages and unique selling points.

Fabric appearance

Thanks to a purposefully held weft tension before beat-up, a very uniform, reproducible fabric image is created.

High versatility

The projectile loom can be set up quickly and easily for completely different fabrics and working widths.

Low weft tension

Since only one acceleration and braking phase occurs on the projectile loom, the weft tension level is generally low.

High productivity

The various machine settings are easily reproducible and extremely stable over several shifts during production.

Free mixing of yarns

Different yarns and yarn counts can be mixed and inserted in any order during the weaving process.

High fabric quality

The lack of weft transfer during weft insertion potentially eliminates downtime and prevents damage to the fabric center.

Green production

With our conversion concept, we are leading high-quality technology into the next generation and thus preventing fully functional machines from being replaced by weaving machines with a significantly shorter lifetime.

We carry out our work selectively in such a way that it achieves maximum effect with minimum effort.

Experience shows the low energy consumption of projectile weaving machines. You not only avoid high investments, but also maintain low operating costs.

The Know-How

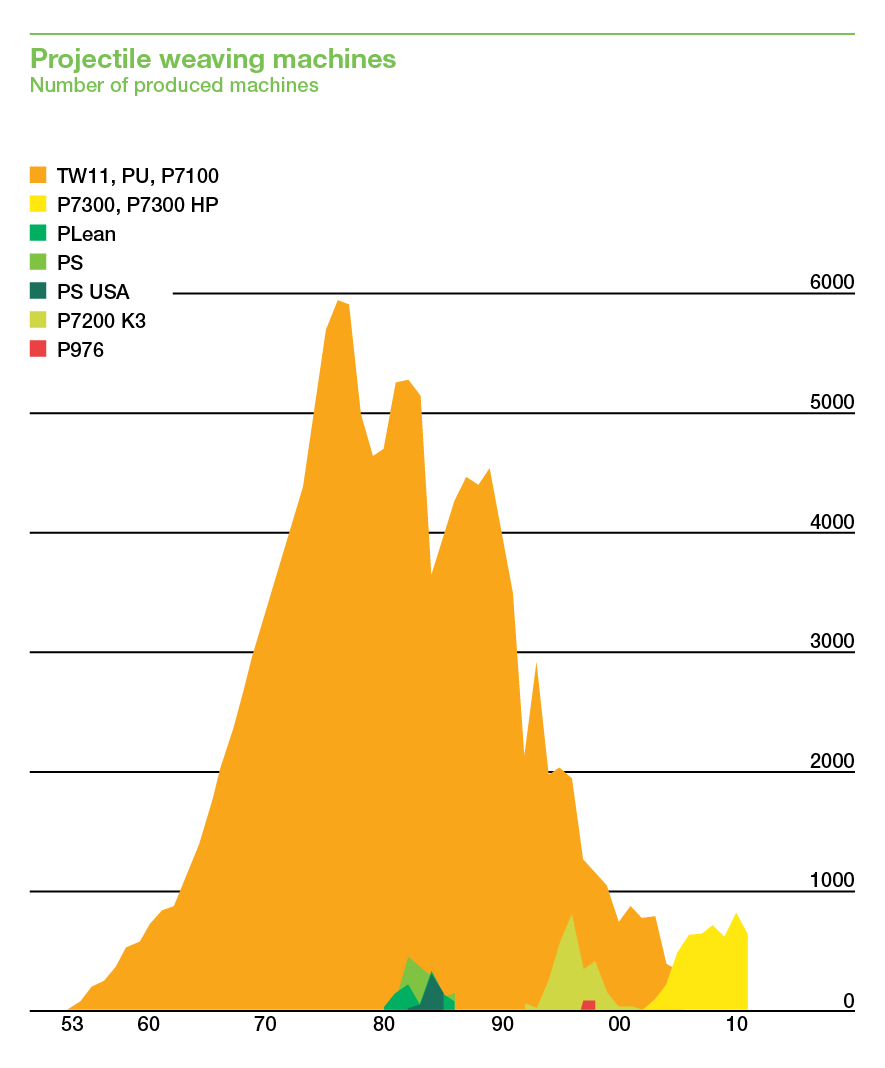

More than 150,000 projectile weaving machines have been produced and sold worldwide. The knowledge about this specialized technology seemed to be slowly being lost. Gianfranco Di Natale asked himself the fundamental question of how this enormous potential can be converted back into meaningful productivity.

In the solution approach, he deliberately focused on the positive weft insertion and developed it further in a targeted manner. It reduced the universality of the machine, which was no longer required, and significantly increased the fabric quality with higher performance and lower machine stress.

Gianfranco Di Natale can look back on over 16 years of experience in the development of projectile weaving machines. He worked for 12 years at Sulzer Rüti and Sulzer Textil (P7150, P7250) and was responsible for the latest major developments of P7300 and P7300HP. He dealt so intensively with the technology that he can translate technical textile tasks almost intuitively into mechanical and electronic solution concepts.

The Product

Our product is a conversion kit consisting of various modules that optimize selected areas of the machine. One includes tools for quality assurance, machine setting or machine monitoring. The modules function independently, but can also be combined as desired. The following options are available:

- You order individual components or the entire set and build it on its own

- You define your requirements. We carry out a thorough analysis and adapt the modules to your needs

projectile

Weight-optimized projectiles extend the weft yarn spectrum by improving insertion quality and performance. Customers with D2 projectile can switch to the R12heavy dimension with a corresponding increase in performance.

weft tensioner

The geometry and movement of the weft tensioner defines the insertion tension and determines the fabric quality decisively. Thread reserve and thread tension can be realized according to customer-specific requirements.

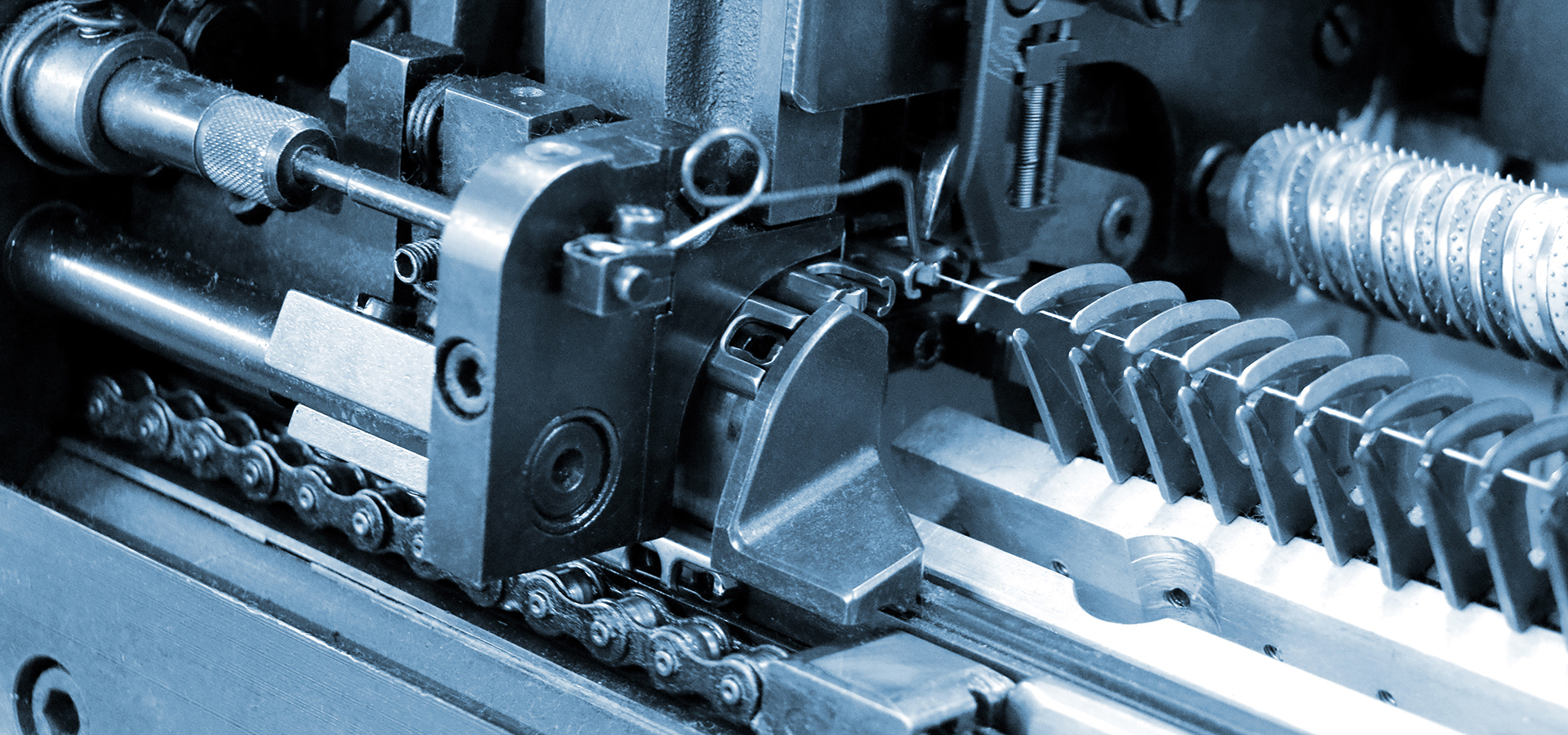

picking lever

Together with the weight-optimized projectiles, a geometrically modified picking lever increases the insertion performance. At the same time, it reduces the temperature of the oil brake housing.

guide teeth

Modified guide teeth enable higher warp densities and higher fabric qualities. The trend is developing to individualize the projectile loom to a specific yarn spectrum according to customer requirements.

tools

Our tools are mainly used in quality assurance, machine setting or machine monitoring. It supports optimal and resource-saving operation as required by means of electronic setting aids and sophisticated setting tools.

conversion kit for total overhaul (in preparation)

Based on the modules «projectile», «weft tensioner», «picking lever» and «guide teeth», this kit contains the core parts of the mechanics. This conversion kit realizes a maximum of quality and performance increase.

The Company

We are a company that follows the standards of Industry 4.0. We provide engineering services in a network of specialists. For the production of the components we work together with selected Swiss manufacturers.

If you are faced with a major decision or have questions about quality or performance optimization, call us.

The Network

A dedicated network has developed around the generic terms “Rüti”, “Sulzer” and “Projectile weaving machines“. There is a lively exchange of knowledge and experience between the members. Since universities, technical colleges and a weaving museum as well as former Sulzer employees, customers and suppliers are part of this network, the area continues to develop at a high level. We are a member of the Swiss Textile Machinery.

Technology Tutorial

Why Rüti Textil

Upgrade your Loom

Get in Touch for an estimate!

We are leading high-quality technology into the next generation

RÜTI TEXTIL

Rüti Textil GmbH

Postfach 632

CH-8630 Rüti

info@rutitextil.ch

www.rutitextil.ch

NEWSLETTER